Quality Control Process

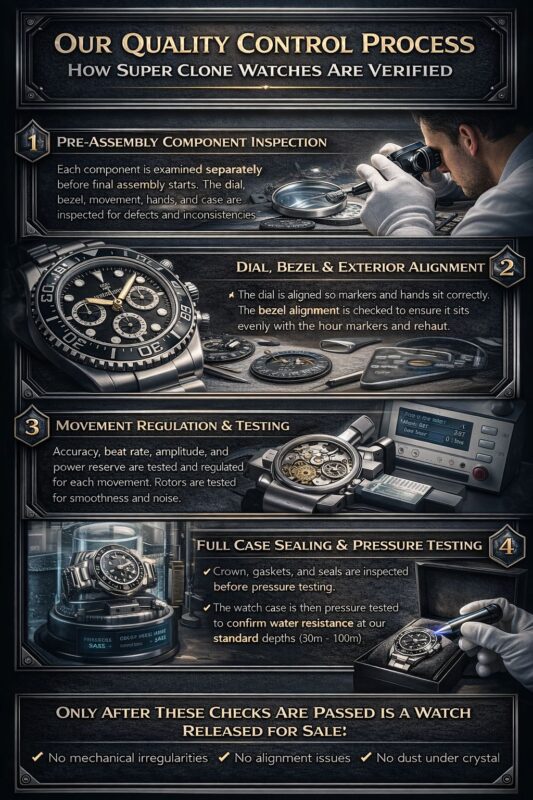

Our Quality Control Process: How Super Clone Watches Are Verified

When discussing super clone watches, most focus on how closely a watch looks to the original. At SuperCloneWatches.com, we take a different approach. Quality for us is about verification, consistency, and real-world performance — not just product page claims. Learn how this integrates with craftsmanship and materials and factory standards.

Why Quality Control Matters

Even high-end factory units can vary. Without proper QC, buyers may encounter:

- Misaligned dials or date windows

- Bezels that don’t line up

- Loose bracelets or weak clasps

- Movement issues that appear after a few days (movement function and stability)

These seemingly minor problems can turn excitement into disappointment, which is why our QC process is foundational.

Our Approach to Quality Control

We view QC as a verification process:

- Every watch is inspected individually

- Factory reputation alone is never enough (factory evaluation)

- Approval requires confidence in three areas: looks, function, and wearability

Step One: Visual Accuracy and Alignment

Dial Layout and Printing

- Logo placement

- Font spacing and thickness

- Marker alignment

- Date window positioning

Even small misalignments fail this stage.

Bezel Alignment

- Centering at 12 o’clock

- Engraving depth and clarity

- Smooth, even rotation

Step Two: Case, Crystal, and Finishing

Case Shape and Finish

- Symmetry and polish consistency

- Transitions between brushed and polished surfaces

- Smooth feel and balanced wrist presence

Sapphire Crystal Clarity

- Crystal fit and clarity

- Anti-reflective coating quality

- Automatic rejection for cloudy or poorly seated crystals

Step Three: Bracelet and Clasp Inspection

Bracelet Construction

- Link consistency

- Screw security

- Articulation and flexibility

Clasp Function

- Opening and closing action

- Locking strength

- Even pressure when closed

Step Four: Movement Function and Stability

Basic Operation Checks

- Smooth seconds hand sweep

- Crown winding feel

- Hand-setting accuracy

- Correct operation of date, GMT, or chronograph functions

Stability and Power

- Power reserve consistency

- Stable timekeeping

- Proper engagement of complications

These checks are in line with our Swiss clone movement standards.

Step Five: Overall Balance and Wearability

- Weight distribution

- Comfort during daily wear

- Bracelet fit and drape

- Overall wrist feel

Transparency Through QC Media

We provide real QC photos and videos whenever possible, including:

- Close-up dial shots

- Bezel alignment photos

- Bracelet and clasp views

- Short movement operation videos (water resistance testing context)

Handling Watches That Don’t Pass QC

- They are not shipped

- Rechecked or replaced

- The process starts over with a different unit if needed

How Our Process Protects Buyers

Structured QC reduces:

- Visual disappointments

- Early mechanical issues

- Post-delivery disputes

- Return and replacement problems

Consistency builds trust — many customers return not for hype, but for predictability. See our homepage overview for complete standards across all watches.

Our Long-Term Commitment

We don’t claim perfection, but we do commit to:

- Honest verification

- Clear QC standards

- Accountability in sourcing, inspection, and communication

A Final Thought

When comparing super clone watches, look at how QC is explained. Vague promises are common; clear, structured verification is rare. We provide transparency so buyers understand exactly how watches are verified and inspected across