Craftsmanship & Materials

Craftsmanship & Materials Behind Our 1:1 Super Clone Watches

At SuperCloneWatches.com, craftsmanship is not just a marketing term — it is the core of how we select, inspect, and deliver every watch. We focus on how a watch is built, feels in daily wear, and accurately reflects the original design. This guide details the materials we use and the processes we follow to guarantee consistent, high-quality results. Learn how this integrates with our quality control process and factory standards.

Case Materials & Crystal Quality

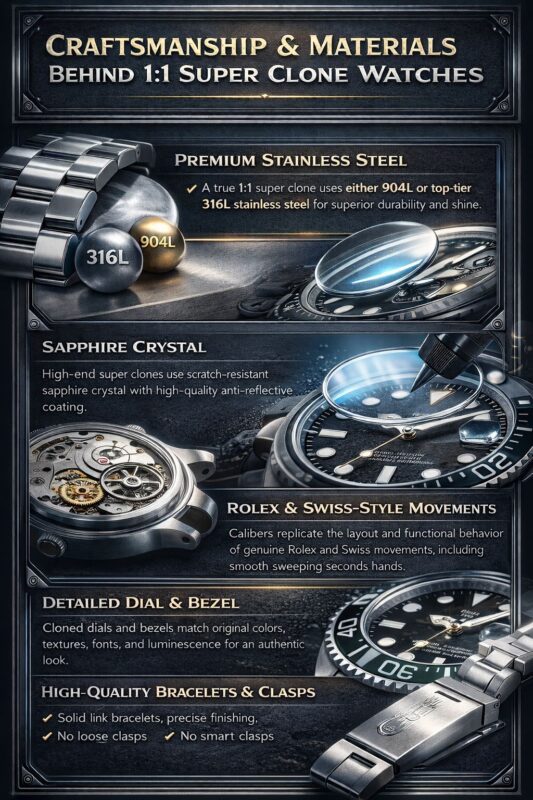

The materials used in a watch are just as important as the movement. They determine weight, comfort, durability, shine, realism, and long-term wearability. High-quality materials instantly separate a premium 1:1 super clone from a cheap imitation.

904L Stainless Steel

Premium Grade — Top Super Clones

- Stronger & more corrosion-resistant than 316L

- Brighter, richer shine & luxury feel

- Holds polishing extremely well

316L Stainless Steel

Great Quality — Mid-Tier Models

Scratch-Proof & Premium Looking

- Highly durable & scratch-resistant

- Lightweight & comfortable

- Great value while maintaining luxury feel

Ceramic Bezels

Scratch-Proof & Premium Looking

- Scratch-proof & fade-resistant

- Premium glossy finish

- Resistant to wear, heat & UV light

Sapphire Crystal

Top-Tier — Best Glass

- Extremely scratch-resistant

- Clear visibility with AR coating

- Mimics real luxury watch glass

AR Coating

Enhanced Dial Visibility

- Removes glare in bright sunlight

- Improves clarity

- Mimics real Swiss finishing

Rubber, Leather & Steel Bracelets

Choose Based on Lifestyle

- Solid-link steel: heavy & realistic

- Leather: comfortable & elegant

- Rubber: flexible, sporty, modern

Which Materials Should You Choose?

Optimal combination for premium super clones:

- Case Material: 904L Steel — Most realistic & shiny

- Crystal: Sapphire — Scratch-proof & clear

- Bezel: Ceramic — Durable & fade-proof

- Bracelet: Solid-Link Steel — Premium feel & weight

- Coating: AR Coating — Better visibility

This combination gives the unmistakable “luxury wrist presence” collectors love.

How We Approach Craftsmanship at SuperCloneWatches.com

Our quality process begins long before a watch reaches a customer. We partner only with factories that meet strict material and construction standards, avoiding mass-market replicas that prioritize quantity over accuracy. See our full factory evaluation process.

What Craftsmanship Means to Us

- Correct materials, never substitutes

- Accurate machining, no shortcuts

- Finishing that lasts over time

- Watches built for daily wear, not just display

Every model we offer is carefully selected based on these criteria and paired with high-grade movements for true 1:1 functionality.

The Materials We Use in Our 1:1 Super Clone Watches

Materials define how a watch wears, ages, and performs. We scrutinize every external component to ensure authenticity and durability.

Stainless Steel: 904L and 316L

Depending on the model, our watches use either 904L or high-grade 316L stainless steel. 904L steel matches the original design with superior polish and corrosion resistance, while 316L ensures long-term stability and ease of maintenance. Steel selection is always based on accuracy, not trends.

Ensuring Proper Case Finishing

- Precise case shape and edge definition

- Polished and brushed surface transitions

- Symmetrical crown guards and lugs

Poor finishing is an easy indicator of a low-grade replica. Our finishing aligns with our QC standards for consistency.

Sapphire Crystal and AR Coating Standards

All 1:1 super clone watches feature sapphire crystal for high scratch resistance, long-term clarity, and authentic dial appearance. Depending on the reference, watches use single or double anti-reflective (AR) coating to improve visibility without distorting color or contrast.

Bracelet Construction and Clasp Quality

- Solid links and proper weight balance: natural wrist feel, reduced looseness, improved durability

- Clasp fit and function: smooth operation, secure locking, precise alignment

Durability and Everyday Wear Standards

Our watches are built for real use. Each case is assembled with proper gaskets and sealing to handle normal daily exposure, verified through water resistance testing. We ensure watches maintain finish, bracelet tightness, and stable operation over time.

Factory Selection and Quality Control Process

We work exclusively with top-tier factories known for consistent materials, precision machining, and finishing quality.

Factory Partner Evaluation

- Material sourcing and quality

- Machining accuracy

- Finishing consistency

- Batch reliability over time

Quality Control Standards

- Case and dial alignment checks

- Crystal clarity inspection

- Bracelet and clasp function testing

- Overall finishing quality approval

Only watches meeting our standards move forward to customers, ensuring each piece passes QC inspection.

Why Material Accuracy Matters

Material accuracy is critical for wearability, longevity, and performance. At SuperCloneWatches.com, true 1:1 super clone quality is defined by careful construction, not marketing claims.

Our Commitment to Craftsmanship

We aim to deliver watches that reflect meticulous selection, consistent standards, and durable construction. We do not sell low-grade replicas or rely on exaggerated descriptions. Our goal is simple: to provide well-built super clone watches that customers can wear, trust, and enjoy over time. Visit our homepage overview for complete guidance on super clone watch standards.